System Characteristics

Chapter 5 Page 3

Sealed System Failures

There are a few most common failures that could happen to affect the sealed system.

1. Overcharge - Overcharges can but rarely happen from the factory, if a system is overcharged with refrigerant this is usually because someone has serviced it and incorrectly charged it with freon.

2. Undercharge - This too is rare to happen from the factory, if a system is undercharged with refrigerant this is usually because someone has serviced it and incorrectly charged it with freon.

3. Low Side Leak (Some refrigerant still in the system)

4. Low Side Leak (No Refrigerant left in the system

5. High Side Leak

6. Low Capacity Compressor

7. Capillary Tube Restriction (Complete Blockage)

8. Capillary Tube Leak (Partial restriction or Floating Restriction

Below are examples of problems which may be found in a Sealed System.

1. Overcharge - This is when the unit was manufactured or serviced by a technician and more refrigerant was added to the system than designed. Overcharging raises system pressures and with the rise of pressure intern creates a rise in refrigerant temperature. This affects the performance of the system and all pressures are higher than normal. Again, overcharges are caused by poor system processing. The chances of a system being overcharged at the factory are minimal. As we’ve already learned, over charging a system plays havoc with pressures, cooling capacity and power consumption. Diagnosing an overcharge begins by taking a current reading of the compressor. If the current draw, the system pressures and the system temperatures all point to a system failure, attach gauges to confirm your suspicions.

Here are the symptoms of an overcharge.

2. Undercharge- This is when the unit was manufactured or serviced by a technician and less refrigerant was added to the system than designed. Undercharging lowers system pressures and would cause an evaporator to not operate to its fullest capacity. This affects the performance of the system and all pressures are lower than normal. Conditions and diagnosis of an undercharge are identical to that of a leak.

Here are the symptoms of a blocked condenser fan.

3 Low Side Leak (Some Refrigerant Still In The System)- This is when the components on the low side of the system are leaking such as evaporator, or suction line. The refrigerant as it leaks out will make the low side pressure pressure go into a vacuum when the compressor is running. This also allows air and non condensables to get pulled into the system. An empty system resulting from a low side leak displays odd characteristics that may not always be easy to diagnose. Depending on how much air the system has absorbed, compressor current draw and high side pressures could vary from slightly above normal to very high. The higher than normal pressures and temperatures are caused by the air in the system. Air is a non condensable, meaning that no amount of pressure or cooling will cause the air to condense. Pressure just continues to build and, along with the higher pressures, much warmer temperatures.Because of the loss in cooling capacity, the thermostat never satisfies and the unit runs continually. Just as with any leak, a check of the evaporator frost pattern will verify that there is no refrigerant left in the system.

The difference between this condition and other leaks is best seen when gauges are attached to the system. The high side pressure will be much higher than normal (sometimes in excess of 200 PSIG). Low side pressure will vary from 0 psig to a slight vacuum.

Because the compressor is attempting to push more and more air into the condenser and the air never condenses, current draw increases. The compressor dome may become too warm to touch.

Here are the symptoms of a High Heat Load.

4 Low Side Leak (No Refrigerant In The System)- Once all of the refrigerant has escaped the system, no further cooling takes place. There is no evaporation going on, thus there is no frost pattern on the evaporator. There is no refrigerant to condense so the liquid level is non existent. Condenser temperatures drop. Because of the loss in cooling capacity, the thermostat never satisfies and the unit runs continually Unlike a low side leak, the chance of air being pulled into the system is not as great. As long as the compressor is running and there is refrigerant in the system, the high side pressure never goes into a vacuum. And, as long as there is any positive pressure in the high side, it’s impossible for air to infiltrate the tubing With little or no refrigerant in the system, the low side of the system will go into a very deep vacuum (around 30 PSI on the manifold gauge set). High side will show a slight positive pressure. Note: On a system that is totally empty of refrigerant, it is possible for air to infiltrate if the unit looses power. Remember that without refrigerant, the low side of the system will drop to a very low vacuum. If the unit is unplugged and the compressor stops, the system will attempt to equalize and could pull air into the system.

Here are the symptoms of a Low Side Leak (No refrigerant in System).

5 High Side Leak- Once all of the refrigerant has escaped the system, no further cooling takes place. There is no evaporation going on, thus there is no frost pattern on the evaporator. There is no refrigerant to condense so the liquid level is non existent. Condenser temperatures drop. Because of the loss in cooling capacity, the thermostat never satisfies and the unit runs continually Unlike a low side leak, the chance of air being pulled into the system is not as great. As long as the compressor is running and there is refrigerant in the system, the high side pressure never goes into a vacuum. And, as long as there is any positive pressure in the high side, it’s impossible for air to infiltrate the tubing With little or no refrigerant in the system, the low side of the system will go into a very deep vacuum (around 30 PSI on the manifold gauge set). High side will show a slight positive pressure. Note: On a system that is totally empty of refrigerant, it is possible for air to infiltrate if the unit looses power. Remember

that without refrigerant, the low side of the system will drop to a very low vacuum. If the unit is unplugged and the compressor stops, the system will attempt to equalize and could pull air into the system.

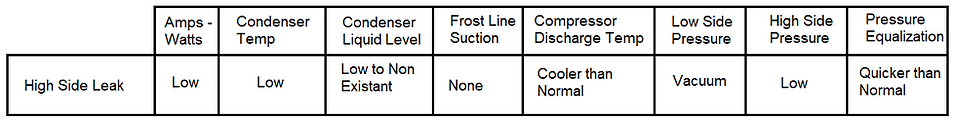

Here are the symptoms of a High Side Leak.

6 Low Capacity Compressor - Compressors lose their efficiency when one of the two valves that control refrigerant flow in and out of the compression chamber fails to seat properly. If the intake valve fails, refrigerant is pulled into the compression chamber during the intake stroke of the compressor in the normal manner. On the exhaust stroke however, instead of all of the refrigerant in the chamber being directed into the condenser, some of the refrigerant is pushed back into the dome of the compressor. A defective exhaust valve will have a similar effect. On the exhaust stroke the refrigerant is pushed into the condenser. On the intake stroke, not only does the compressor pull refrigerant from the dome of the compressor but some of the refrigerant that was directed into the condenser is pulled back into the chamber. Net result of either valve failing is the compressor loses it’s ability to set up the correct pressure differential required for proper evaporation and condensing of the refrigerant. Low side pressure rises and high side pressure drops.

Here are the symptoms of an Low Capacity Compressor.

7 Capillary Tube Complete Restriction - Restrictions occur when salts or other debris blocks the flow of refrigerant through the cap tube. Other possibilities are: The manufacturing site pushed the cap tube too far into the drier and the tubing came to rest on the screen (blocking the flow of refrigerant). Too much solder was used when the cap tube was brazed to the drier and solder wicked to the end of the cap tube to plug it. A visual inspection of the evaporator will make this condition appear much like a leak. There will be no frost on the evaporator. Current draw will be lower than normal and the low side of the system will be in a deep vacuum. The compressor and condenser temperatures will be lower than normal. The difference is that, unlike a leak where there is no refrigerant in the system, all of the refrigerant is trapped in the condenser. Note: For most technicians, the concept of lower than normal condenser pressures when all of the refrigerant is trapped in the condenser seems foreign.

They reason that if refrigerant flow is blocked, the pressure should be higher than normal. They forget that once the refrigerant re-condenses back into a liquid and is now trapped in the condenser, the condenser acts as a storage vessel. Just as the pressure of refrigerant in a cylinder is dependent on the ambient temperature, the pressure of the condenser will depend on the temperature of the kitchen (or wherever the refrigerator is installed).

Here are the symptoms of Capillary Tube with a Complete Restriction.

8 Capillary Tube (Partial/Floating Restriction) - The capillary tube is the smallest internal diameter tubing in the sealed system. Oil and or Non-Condensables can sometimes pass through the Drier Filter and partially restrict the flow, or even block the flow temporarily. This will look similar tot he image on the right. The low side pulled into a vacuum and the high side pressure is higher than normal.

Here are the symptoms of Capillary tube Partial/Floating Restriction.

Link to manual used in video