Service Tools

Chapter 4 Page 2

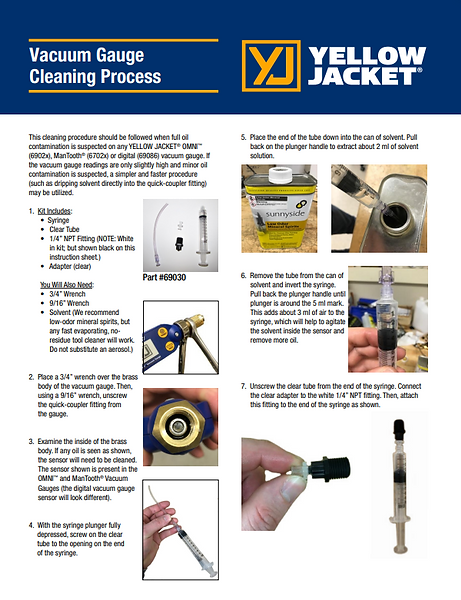

MANOMETER

A closed-end mercury manometer (Image on the right) is a necessary instrument to properly and efficiently test and repair a sealed refrigeration system. It is needed to accurately measure deep vacuums which must be pulled on the system in normal service.

This is used before you add the refrigerant to charge the system. With the the changes in technology a micron gauge is used to measure the vacuum. This will insure the system is not leaking and there is no moisture or Non-Condensable. Properly used, the manometer will indicate if a leak or moisture exists in the system.*

Vacuum in inches of mercury is measured by determining the difference between the mercury level in the two tubes, then subtracting this difference reading from 30 This should always be the case when a reading is taken. In our example, the left side reads .1 inch above zero and the right side .1 inch below zero. The difference, therefore, is .2 inch. Subtracting this difference from 30 inches, the vacuum reading is 29.8 inches of mercury. The top of each mercury column is actually convex which can lead to an inaccurate reading. Read either the top or bottom of the hump, but be certain to read both columns in the same way.

Care of the manometer requires that the keeper must always be in place when the instrument is not in use to prevent the mercury from becoming displaced or lost, and to keep air and moisture

*Reaction of the manometer to:

A leak in the system, the reading will continue to change until it reaches atmospheric pressure.

Moisture in the system will cause a change in the reading to a point and then it will stabilize.

This devices is installed on the Process Hose of the gauges. Once 500 Microns are reached the system is ready to charge with freon.

Micron Gauges Old Style Mercury Manometer

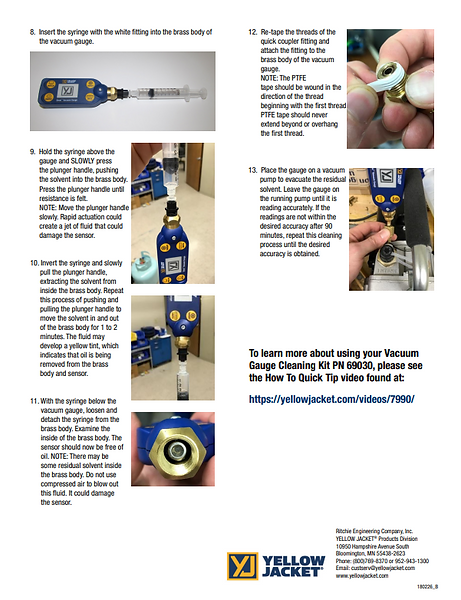

Usage Instructions Yellowjacket.com

Maintenance and Cleaning Instructions Yellowjacket.com